back to the overview |

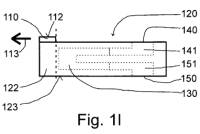

POLY-01: Polyvalent Cooling A substrate for mounting semiconductor elements comprises cooling channels outside of the projection of the semiconductor element and can be cooled directly by a coolant or by a separate cooling body |

| ||||

|

Claims (PCT application WO 2009 103 531 A1): 1. A heat transfer apparatus (15) comprising at least one semiconductor component (10) and at least one heat-conducting body (20), wherein the semiconductor component (10) comprises at least one pn junction which generates heat during operation of the semiconductor component and a heat source region which includes all pn junctions which generate heat during operation of the semiconductor component (10) in the semiconductor component, as well as at least one contact surface (11, 12), and the heat-conducting body (20) comprises at least one receiving surface (21) which has at least one firmly bonded connection to the contact surface (11, 12) of the semiconductor component (10), and also at least one channel structure (30, 31) which is provided for convective heat transfer to at least one first coolant which can be guided through the channel structure (30, 31), characterised in that the channel structure (30, 31) of the heat-conducting body (20) is disposed completely outside a heat source projection (22) of the heat source region extending perpendicular to the contact surface (11, 12), and the heat-conducting body (20) has at least one connecting surface (23) via which at least one conductive heat transfer to at least one heat-removing body (98) is provided which comprises at least one heat transfer structure (35), wherein at least one convective heat transfer optionally takes place at least to the first coolant or to at least a second coolant flowing through the heat transfer structure (35). 2. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the heat transfer apparatus (15) comprises two or more semiconductor components (10) which each comprise at least one pn junction which generates heat during operation of the semiconductor component (10). 3. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the conductive heat transfer from the connecting surface (23) to the heat-removing body (98) takes place via at least one heat-receiving body (90), which has at least one connecting surface for the conductive heat transfer to the heat-removing body (98), wherein the connecting surface of the heat-receiving body (90) is greater than the connecting surface of the heat-conducting body (20), the heat-receiving body (90) has at least one firmly bonded connection to the connecting surface (23). 4. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the heat transfer structure (35) of the heat-removing body (98) has at least one channel structure with a plurality of channels and/or is present at least in sections in a fin and/or column structure. 5. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the first coolant flows both through the channel structure (30, 31) and also through the heat transfer structure (35). 6. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the convective transfer takes place both to the first coolant and also to the second coolant. 7. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the second coolant is gaseous. 8. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the firmly bonded connection of the receiving surface (21) to the contact surface (11, 12) comprises at least one transition body. 9. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the channel structure (30, 31) comprises two or more channels which are disposed in the heat-conducting body and are connected to at least one inlet opening (40) and/or at least one outlet opening (50). 10. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the connecting surface (23), the receiving surface (21) and the heat transfer structure (35) of the heat-removing body (98) are disposed at least in sections in the heat source projection (22). 11. The heat transfer apparatus (15) according to any one of claims 1 to 9, characterised in that the connecting surface (23) is disposed on an end surface inclined with respect to the contact surface (11, 12) by at least approximately 90o. 12. The heat transfer apparatus (15) according to claim 11, characterised in that the heat source projection (22) extends as far as the end surface. 13. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the semiconductor element (10) is an edge-emitting electro-optical component having a first contact surface (11) and at least one second contact surface (12) opposite to said first contact surface (11), at least in sections and having at least one light exit surface which is disposed between the two contact surface planes, which is inclined with respect to the contact surfaces (11, 12) by an angle of at least approximately 90o, and defines a light emission direction (13) which is oriented perpendicular to the light exit surface in the direction facing away from the semiconductor component (10). 14. The heat transfer apparatus (15) according to any one of the preceding claims, characterised in that the channel structure (30, 31) consists of a plurality of channels which are elongate at least in sections, whose longitudinal axes are disposed perpendicular to the contact surface (11, 12) and which extend from an upper side of the heat-conducting body (20) parallel to the contact surface to an underside of the heat-conducting body (20) opposite the upper side. 15. The heat transfer apparatus (15) according to any one of the claims 1 to 13, characterised in that the channel structure (30, 31) in the heat-conducting body (20) is formed by a plurality of grooves which are parallel to one another, inclined with respect to one another or intersect one another, which are incorporated in the surface region of a side of the heat-conducting body (20) facing the semiconductor component (10), which is aligned substantially parallel to the contact surface (11, 12), wherein the grooves are terminated at least in sections by a cover element (60, 80) and a first section of the grooves is connected to a first opening (61, 47) in the cover element and a second section of the grooves is connected to a second opening (62, 57) in the cover element (60, 80). 16. A method, in particular a test method, for setting up and operating a heat transfer apparatus (15) according to any one of the preceding claims, comprising the following steps: a) firmly bonded connection of the at least one semiconductor component (10) to the heat-conducting body (20), b) allowing a liquid, first coolant to flow through the channel structure (30, 31) of the heat-conducting body (20) and test operation of the at least one semiconductor component (10), in particular for carrying out functional testing of the at least one semiconductor component (10), associated with the detection of at least one parameter, c) connecting the heat-removing body (98) to the heat-conducting body (20), d) operating the semiconductor component (10) optionally with the liquid first coolant flowing through the channel structure (30, 31) of the heat-conducting body (20) or with the liquid first coolant or a second coolant flowing through the heat transfer structure (35) of the heat-removing body (98). 17. The method, in particular a test method, for setting up and operating a heat transfer apparatus (15) according to any one of claims 1 to 15, comprising the following steps: a) firmly bonded connection of the at least one semiconductor component (10) to the heat-conducting body (20), b) setting up a detachable connection between the heat-conducting body (20) and a heat-removing device, c) allowing a first coolant to flow through the heat-removing device and test operation of the at least one semiconductor component (10), in particular for carrying out functional testing of the at least one semiconductor component (10), associated with the detection of at least one parameter, d) releasing the connection between the heat-conducting body and the heat-removing device, e) setting up a firmly bonded connection between the heat-conducting body (20) and the heat-removing body (98), f) operating the semiconductor component (10) optionally with the first or second coolant flowing through the channel structure (30, 31) of the heat-conducting body (20) or flowing through the heat transfer structure (35) of the heat-removing body (98). 18. The method, in particular a test method, for setting up and operating a heat transfer apparatus (15) according to any one of claims 1 to 15, comprising the following steps: a) firmly bonded connection of the at least one semiconductor component (10) to the heat-conducting body (20), b) setting up a connection between the heat-conducting body (20) and a heat-removing body (98), c) allowing a liquid first coolant to flow through the channel structure of the heat-conducting body (20), allowing the liquid first coolant or a second coolant to flow through the heat transfer structure (35) of the heat-removing body (98) and test operation of the at least one semiconductor component (10), in particular for carrying out functional testing of the at least one semiconductor component (10), associated with the detection of at least one parameter, d) operating the semiconductor component (10) optionally with the liquid first coolant flowing through the channel structure (30, 31) of the heat-conducting body or with the liquid first coolant or a second coolant flowing through the heat transfer structure (35) of the heat-removing body (98). 19. The method for setting up and operating a heat transfer apparatus (15) according to any one of claims 1 to 15, characterised in that at least two of the methods according to claims 16 to 18 is used. 20. The method according to any one of claims 16 to 19, characterised in that the semiconductor component (10) is an electro-optical component and in at least one test operation, at least one of the following parameters of the electro-optical component is detected: a) electrical operating current, b) electrical operating voltage, c) emitted radiation power and d) spectrum of the emitted radiation. |