back to the overview |

POLY-02: Open-pored substrates Substrate suitable for active cooling of diode lasers and solar cells in an easy configuration of a planar radiation source or a solar module |

| ||||

|

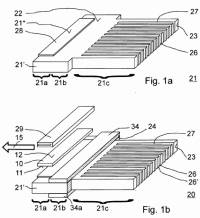

Claims (german utility model): 1. A conversion unit (50/50') for conversion of electrical energy into radiation energy or for conversion of radiation energy into electrical energy comprising at least one conversion arrangement (30/30') and at least one coolant supply and withdrawal device (40) comprising at least one coolant outlet (45a/46a) facing the conversion arrangement (30/30') via which at least one coolant is supplied to the conversion arrangement (30/30'), and at least one coolant inlet (45b/46c) facing the conversion arrangement (30/30') via which the coolant is removed from the conversion arrangement (30/30'), wherein the conversion arrangement (30/30') has a plurality of conversion modules (20/20') which are each arranged adjacent to one another at least in sections in at least one arrangement direction (35/35a, 36/36a) and has at least one coolant guide in the course whereof the conversion module (20/20') is provided with a flow of coolant and the conversion modules (20/20') each have at least one electrically contactable, semiconducting conversion element (10/10') which emits radiation in at least one emission direction (15, 15a) or absorbs emission from at least one irradiation direction (15, 15a) and at least one heat-conducting member (21) comprising at least one heat-absorbing section (21a) which has at least one heat-absorbing surface (21*) to which the conversion element (10) is fastened, at least one heat-emitting section (21c) which has at least one heat-emitting surface (26*) wetted with a coolant for emission of heat to the coolant, characterised in that the heat-emitting section (21) is disposed entirely in at least one heat-conducting direction inclined with respect to the ar-rangement direction (35/35a, 36/36a) in relation to the heat-absorbing section (21a) and has at least one recess (26/26a/26b) embracing the heat-emitting surface (26*) as well as at least one opening (27/27a) which is disposed on at least one first outer side (22/22a) opposite the heat-emitting section (21c) of the heat-conducting member (21) of an adjacent conversion module (20) at least in sections and which is connected to the recess (26/26a/26b), the heat-absorbing section (21a) has no surface wetted by coolant, the coolant guide has coolant flow passages (37) between the heat-emitting sections (21c) of heat-conducting members (21) of adjacent conversion modules (20), is configured for a first coolant flow for flowing through a first group of one or a plurality of conversion modules (20) and a second coolant flow fluidically parallel to the first coolant flow for flowing through at least one second group of one or a plurality of conversion modules (20), the heat-conducting member (21) has at least one heat-conducting section (21b) which is disposed between the heat-absorbing section (21a) and the heat-emitting section (21c) and has at least one sealing surface (24) by which means a seal is made, at least in sections, which contributes to an inclusion of coolant in the coolant flow passages (37) and from the coolant supply and withdrawal device (40) at least one section having the coolant outlet (45a/46a) and/or the coolant inlet (45b/46b) is disposed in the heat-conducting direction away from the conversion arrangement (30/30'). 2. The conversion unit according to claim 1, characterised in that the heat-emitting section (21c) has a plurality of recesses (26/26a/26b) each having at least one heat-emitting surface (26*) which are each connected to at least one opening (27/27a) disposed on at least one first outer side (22/22a) opposite the heat-emitting section (21c) of the heat-conducting member (21) of an adjacent semiconductor assembly (20) at least in sections. 3. The conversion unit according to claim 2, characterised in that the recesses (26, 26a) each have the said opening (27/27a). 4. The conversion unit according to claim 2 or 3, characterised in that the recesses (26/26a) extend from the first outer side (22) in the direction of a second outer side (22a) opposite the first outer side (22) and/or from a second outer side (22a) opposite the first outer side (22) in the direction of the first outer side (22). 5. The conversion unit according to claim 4, characterised in that the recesses (26) extend from the first outer side (22) to a second outer side (22a) opposite the first outer side (22), wherein the recesses (26) each have at least one first opening (27) which is disposed on the first outer side (22) as well as at least one second opening (27a) which is disposed on the second outer side (22a). 6. The conversion unit according to claim 4, characterised in that the heat-emitting section (21c) has a first group of recesses (26) and at least one second group of re-cesses (26a), wherein the recesses of the first group of recesses (26) extend from an intermediate space (48) between the first outer side (22) and a second outer side (22a) opposite the first outer side (22) to the first outer side (22) and the recesses of the second group of recesses (26a) extend from the intermediate space to the second outer side (22a) and the coolant guide is configured for a first coolant flow for flow through the first group of recesses (26) and a second coolant flow fluidically parallel to the first coolant flow for flowing through the second group of recesses (26a). 7. The conversion unit according to claim 4, characterised in that the heat-emitting section (21c) has a first group of recesses (26) and at least one second group of re-cesses (26a), wherein the recesses of the first group of recesses (26) extend from the first outer side (22) in the direction of a second outer side (22a) opposite the first outer side (22) and the recesses of the second group of recesses (26a) extend from a second outer side (22a) opposite the first outer side (22) in the direction of the first outer side (22) and the coolant guide is configured for a serial coolant flow for the successive flow through the first group of recesses (26) and the second group of recesses (26a). 8. The conversion unit according to any one of claims 2 to 7, characterised in that the heat-emitting section (21c) is configured at least in sections as cooling fin members, which has cooling fins (26'/26'a) projecting in the heat-conducting direction from the heat-absorbing section (21a), between which are provided recesses (26/26a) configured for absorbing coolant which can have coolant flowing via at least one opening (27/27a) and/or from which the coolant can flow away via at least one opening (27/27a). 9. The conversion unit according to any one of the preceding claims, characterised in that the heat-conducting member (21) is electrically conductive, at least in certain regions, the electrically conductive region of the heat-conducting member (21) is electrically connected to the conversion element (10) and the heat-emitting section (21c) at least at the surfaces wetted by coolant is provided with at least one layer which is electrically non-conductive or consists of at least one refractory metal. 10. The conversion unit according to any one of the preceding claims, characterised in that the conversion element (10) has at least one first electrical contact surface (11) disposed on a first side and at least one second contact surface (12) of opposite polarity to the first electrical contact surface. 11. The conversion unit according to claim 10, characterised in that the first electrical contact surface of the conversion element (10/10') of a first conversion module (20/20') is electrically connected to the second electrical contact surface of the conversion element of a second conversion module directly adjacent to the first conversion module in at least one arrangement direction. 12. The conversion unit according to any one of the preceding claims, characterised in that the number of groups of conversion modules (20/20') is equal to the number of conversion modules (20/20') so that each group has precisely one conversion module (20/20') and all the conversion modules (20/20') have fluidically parallel flow therethrough. 13. The conversion unit according to claim 12, characterised in that the coolant flow passages (37) in the direction facing the coolant supply and withdrawal device are open and the recesses (26/26a) of the conversion modules are open in the direction facing the coolant supply and withdrawal direction, wherein on the inlet side the coolant is introduced into the recesses (26/26a) of the conversion modules (20/20') from which on leaving, it is divided into respectively two coolant portions which enter through the coolant flow passages (37) of conversion modules (20/20') on mutually opposing sides and there combine with the coolant portions from the respectively next adjacent conversion modules (20/20') in order to leave the conversion arrangement (30) via the coolant flow passage (37) on the outlet side. 14. The conversion unit according to claim 12, characterised in that the coolant flow passages (37) are open in the direction facing the coolant supply and withdrawal direction and are divided into a first family of inlet-side and a second family of outlet-side coolant flow passages, wherein inlet-side and outlet-side coolant flow passages alternate in the arrangement direction (35/35a, 36/36a) and on the inlet side the coolant is divided in the inlet-side coolant flow passages (37) into two coolant portions which flow through the recesses (26/26a/26b) of conversion modules (20/20') disposed on mutu-ally opposing sides of the coolant flow passage (37) and on the outlet side combine in the next adjacent outlet-side coolant flow passages (37) with the coolant portions from the next but one adjacent inlet-side coolant flow passages (37) in order to leave the conversion arrangement (30) on the outlet side via the outlet-side coolant passages (37). 15. The conversion unit according to any one of claims 1 to 11, characterised in that the conversion modules (20/20') are present in a first family of conversion modules (20/20') and at least in a second family of conversion modules (20/20'), wherein in each case at least one conversion module (20/20') of the second family of conversion modules (20/20') is fluidically downstream of at least one conversion module (20/20') of the first family of conversion modules (20/20'). 16. The conversion unit according to claim 15, characterised in that the number of conversion modules (20/20') in one group of conversion modules (20/20') is equal to the number of families of conversion modules (20/20') so that the overall number of conversion modules (20/20') is obtained from multiplying the number of groups with the number of families of conversion modules (20/20'). 17. The conversion unit according to claim 15 or 16, characterised in that the recesses (26/26a) of the conversion modules are open in the direction facing the coolant supply and withdrawal device and the conversion modules (20/20') are present in a first family of inlet-side conversion modules (20/20') and in a second family of outlet-side conversion modules (20/20'), wherein inlet-side and outlet-side conversion modules alternate in the arrangement direction (35/35a, 36/36a) and on the inlet side the coolant is introduced into the recesses (26/26a) of the inlet-side conversion modules (20/20') from which, on leaving, it is divided into two coolant portions which flow through the coolant flow passages (37) of inlet-side conversion modules (20/20') on mutually opposing sides and on the outlet side combine in the next adjacent outlet-side conversion modules (20/20') with the coolant portions from the next but one adjacent inlet-side conversion modules (37) and flows combined through the recesses (26/26a) of the outlet-side conversion modules (20/20') in order to leave the conversion arrangement (30) on the outlet side. 18. The conversion unit according to any one of the preceding claims, characterised in that the heat-absorbing surface (21a) is disposed on the upper side on the heat-conducting member (21) and the sealing surface (24) is disposed at least in sections at the top and bottom on the heat-conducting member (21) and is oriented parallel or inclined by less than 45o to the heat-absorbing surface (21a). 19. The conversion unit according to any one of claims 1 to 17, characterised in that the heat-absorbing region (21a) has a front-side end surface (23a) inclined with respect to the upper and lower side of the heat-conducting member (21), and the sealing surface 24 circumferentially surrounds the heat-conducting member (21) in the heat-conducting section (21b) and is parallel or inclined by less than 45o to the front-side end surface (23a). 20. The conversion unit according to any one of the preceding claims, characterised in that an intermediate piece (34) is disposed between mutually adjacent conversion modules (20/20') in the arrangement direction (35/35a, 36/36a), which intermediate piece has the coolant flow passage (37) in the form of a recess. 21. The conversion unit according to any one of claims 1 to 19, characterised in that a sealing means (33) is provided between mutually adjacent conversion modules (20/20') in the arrange-ment direction (35/35a, 36/36a), which sealing means bridges the distance between the mutually opposed sealing faces (24) of adjacent conversion modules (20/20') or contributes to a sealed bridging of the same and a free space configured as a coolant flow passage (37) is provided between two regions of sealing means. 22. The conversion unit according to any one of the preceding claims, characterised in that the conversion unit is configured as a radiation source (50), wherein the conversion arrangement is a radiation emission arrangement (30), the conversion modules are radiation-emitting semiconductor as-semblies (20) and the semiconducting conversion elements are radiation-emitting semiconductor compo-nents (10). 23. The conversion unit according to claim 22, characterised in that the radiation-emitting semiconductor component is a laser diode element (10) and the semiconductor component is a diode laser element (20). 24. The conversion unit according to claim 23, characterised in that the laser diode element is an edge-emitting laser diode element (10) which has at least one first electrical contact surface (11) on a first side and at least one second electrical contact surface (12) on a second side opposite the first side, and a radiation exit surface inclined with respect to the first and/or with respect to the second contact surface from which radiation is emitted during operation [in] an emission direction (15/15a) and which is firmly bonded to the heat-absorbing section (21) by means of its first side. 25. The conversion unit according to claim 24, characterised in that the heat-emitting section (21c) is disposed at least in sections in projection of the edge-emitting laser diode element (10) perpendicular to the heat-absorbing surface (21*), the heat-conducting direction is oriented perpendicular to the heat-absorbing surface (21*) and the diode laser elements (20) are disposed at least in sections consecutively in a depth direction (36b) parallel to the emission direction (15/15a), wherein in each case the laser diode element (10) of a second diode laser component (20) directly adja-cent to a first diode laser component (20) contrary to the direction of emission is offset with respect to the laser diode element (10) of the first diode laser component (20) contrary to the heat-conducting direction. 26. The conversion unit according to claim 24, characterised in that the diode laser components 20 are disposed in sections above one another in a stacking direction (35/35a) perpendicular to the heat-absorbing surface (21*) and/or perpendicular to the heat conducting direction and the heat-emitting section (21a) is disposed completely outside a projection of the edge-emitting laser diode element (10) pointing in stacking direction (35/35a). 27. The conversion unit according to claim 24 or 26, characterised in that the diode laser components 20 are disposed adjacent to one another in sections in a row direction (36/36a) parallel to the heat-absorbing surface (21*) and/or perpendicular to the heat-conducting direction and the heat-emitting section (21c) is disposed completely outside a projection of the edge-emitting laser diode element (10) running perpendicular to the heat-absorbing surface (21*). 28. The conversion unit according to any one of claims 1 to 21, characterised in that the conversion unit is configured as a radiation receiver (50'), wherein the conversion arrangement is a radiation receiving device (30'), the conversion modules are radiation-absorbing semiconductor assemblies (20') and the semiconducting conversion elements are radiation-absorbing semiconductor components (10'). 29. The conversion unit according to claim 28, characterised in that the radiation receiver is configured as a photovoltaic generator (50'), wherein the radiation-absorbing semiconductor assemblies are solar modules (20') and the radiation-absorbing semiconductor components are solar cells (10'). 30. An optical arrangement (60') comprising a conversion unit (50') according to claim 29, characterised by focusing optics which deflects the bundle of solar rays with increased radiation intensity onto the entirety of the solar cells (10') of the radiation receiving arrangement (30'). |